Uses of Armour Joints in concrete flooring

Definition of Armour Joints in concrete flooring

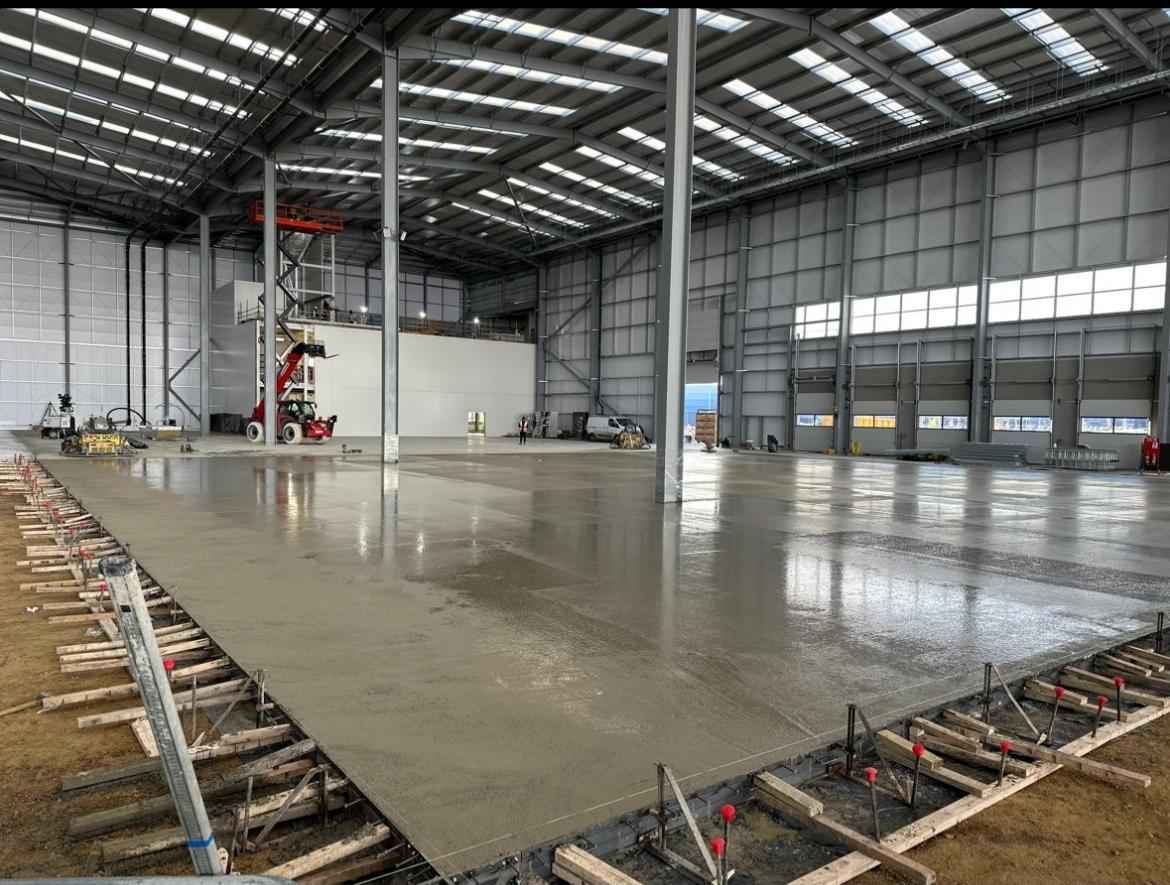

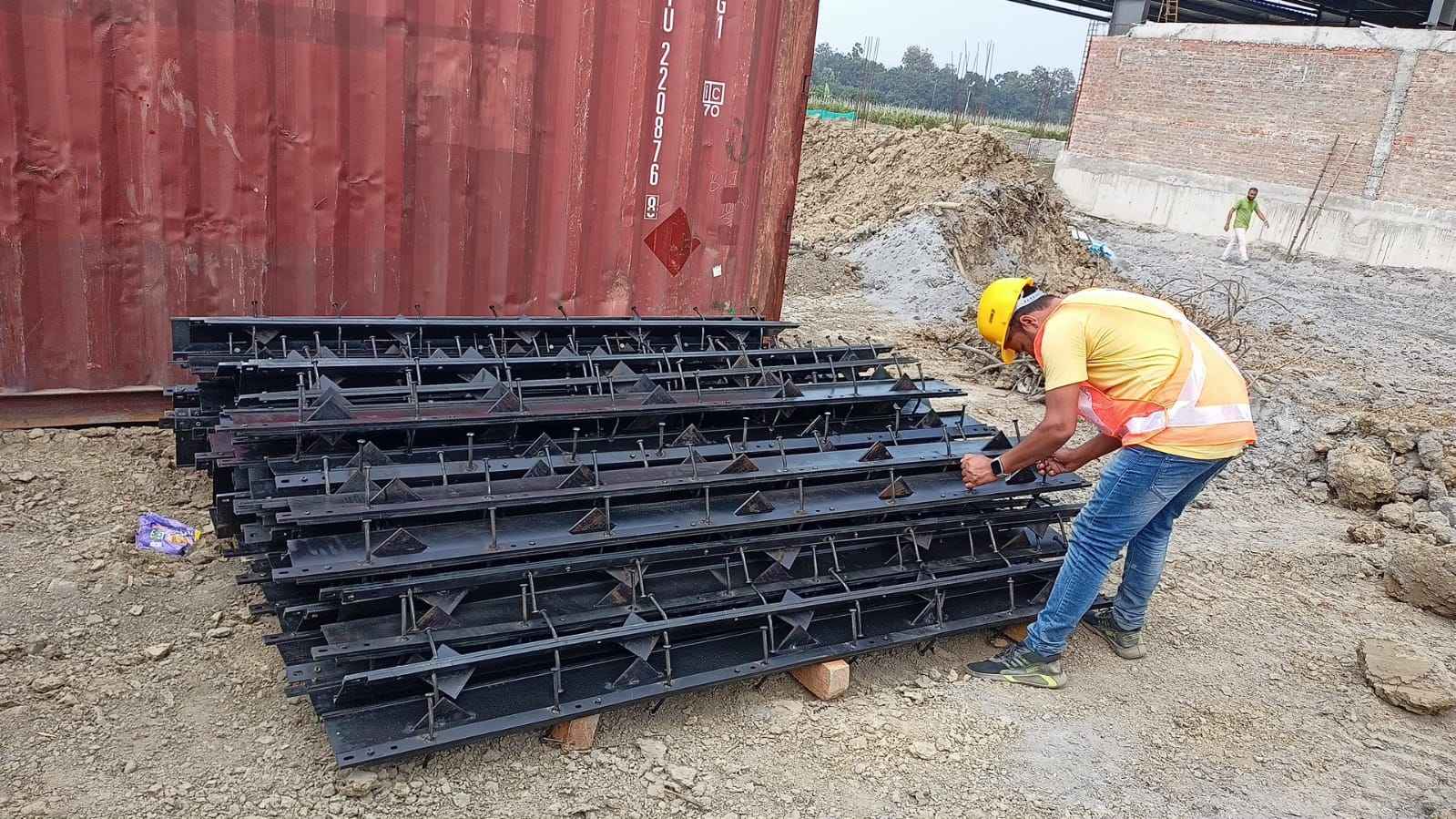

Armour joints, also known as armoured joints, are reinforced expansion or contraction joints used in concrete floors to control cracking, distribute load, and maintain structural integrity. These joints are reinforced with durable materials, typically steel, which strengthens the joint area and prevents premature wear and tear from heavy machinery, foot traffic, and daily wear. Major applications of Armour Joints include warehouses, factories, and logistics centres where forklifts and other heavy equipment frequently move across the floor jointless concrete floor surfaces reinforced with armour joints are particularly beneficial.

How Does Armour Joint Enhance Jointless Floor Construction?

One of the main challenges in concrete flooring is managing the natural expansion and contraction that occurs with temperature changes and load impacts. Concrete, while strong in compression, can crack or spall under tension. Traditional concrete flooring requires regular joint spacing to manage this tension, but these joints often become the site of deterioration over time. Armour joints enable jointless floor construction by reinforcing these areas and reducing the need for frequent joints, resulting in a more seamless floor. Application of armour joints usually to ales lesser maintenance and Provide longevity to the structure. This construction style creates a jointless concrete floor surface that minimises visible lines and joint openings, which not only enhances aesthetics but also improves the floor’s structural resilience. Armour joints help balance flexibility with strength, creating concrete floors that appear jointless yet maintain a robust framework beneath the surface.

Benefits of Armour Joints in Concrete Flooring

a) Crack Prevention for Long-Lasting Durability

One of the primary roles of armour joints is to prevent cracking. By reinforcing vulnerable joint areas, armour joints ensure that any expansion or contraction in the concrete does not result in visible cracks. This added reinforcement enables crack-free concrete flooring that can handle significant load and impact without showing wear or deterioration. With reduced cracking, businesses can save on costly repairs and maintenance over the floor's lifespan. This feature is invaluable in facilities with high daily usage, as it minimises the risk of costly downtime associated with floor repairs.

b) Enhanced Load Distribution

Armour joints improve load distribution across the floor by evenly dispersing the force exerted by heavy equipment and foot traffic. When machinery or pallets are moved over an armour joint, the reinforcement helps to absorb the weight and spread it evenly across the surrounding concrete, rather than focusing pressure on a single area. This feature is crucial in industrial settings, where forklifts, pallet trucks, and other heavy equipment operate continuously. By reducing localised stress on the floor, armour joints contribute to a longer-lasting, more seamless concrete flooring solution.

c) Improved Aesthetic Appeal

Traditional expansion joints can interrupt the visual flow of a concrete floor, creating lines that can detract from a clean, polished look. Armour joints, on the other hand, support jointless floor construction that minimises visible interruptions in the flooring. The result is a smooth, continuous surface that not only looks better but also performs better, especially in spaces where appearance is essential, like retail or showroom floors. This seamless look is a significant advantage for any space prioritising design alongside function. For businesses like warehouses, large retail spaces, and showrooms, a polished, joint-free floor surface can elevate the facility's overall appeal.

d) Reduced Maintenance Requirements

Armour joints contribute to lower maintenance costs by preventing floor damage. Without armour joints, traditional expansion joints often degrade over time, accumulating debris, dirt, and even moisture that can lead to further deterioration. With reinforced armour joints, however, these areas remain resilient and require less upkeep, reducing downtime and maintenance costs. Additionally, armour joints help reduce surface imperfections and damage to machinery, as vehicles and equipment can transition smoothly over joint areas. This smoothness minimises wear on wheels and other moving parts, thereby lowering equipment maintenance needs over time.

Application of Armour Joints in Various Industries

Armour joints are adaptable and beneficial across multiple industries. Here are some common applications where armour joints contribute to a durable and crack-free concrete flooring system:

- Warehousing and Distribution Centers: In warehouses, armour joints allow for smooth transitions across aisles, improving the durability of high-traffic zones where pallets, forklifts, and trucks frequently operate.

- Manufacturing Plants: Manufacturing facilities often use armour joints in areas where heavy machinery operates, reducing wear and tear and enhancing floor longevity.

- Retail Spaces: For retail spaces requiring a polished, seamless look, armour joints offer aesthetic appeal while withstanding foot traffic and load from displays and shelving.

- Food and Beverage Facilities: Armor joints in food processing plants enhance hygiene and durability by minimising joint openings that could trap debris, ensuring a seamless concrete flooring surface that’s easier to clean.

In summary, armour joints are a critical component in creating crack-free concrete flooring that performs well under heavy loads and intense traffic. Their ability to prevent cracking, distribute loads, and enhance floor appearance makes them a go-to solution for industries aiming to maximise floor lifespan while minimising maintenance needs.